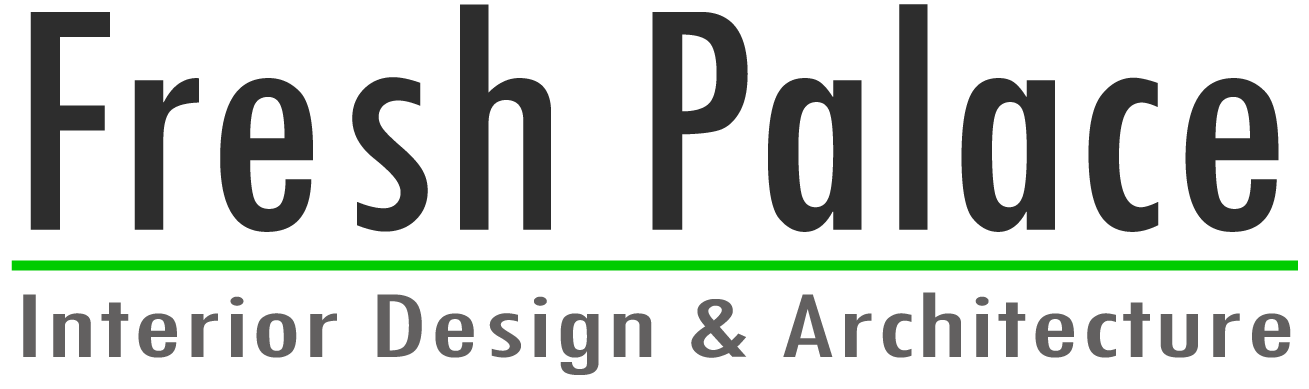

Rock Reach House, Mojave Desert

Rock Reach House was completed in 2010 by the Palm Springs based studio o2 Architecture. This 1,000 square foot Prefabricated home was built as a prototype for Blue Sky Homes. The property is located in the Mojave Desert of California, USA.

Rock Reach House is available for vacation rental, more information can be found here.

Rock Reach House, Mojave Desert by o2 Architecture:

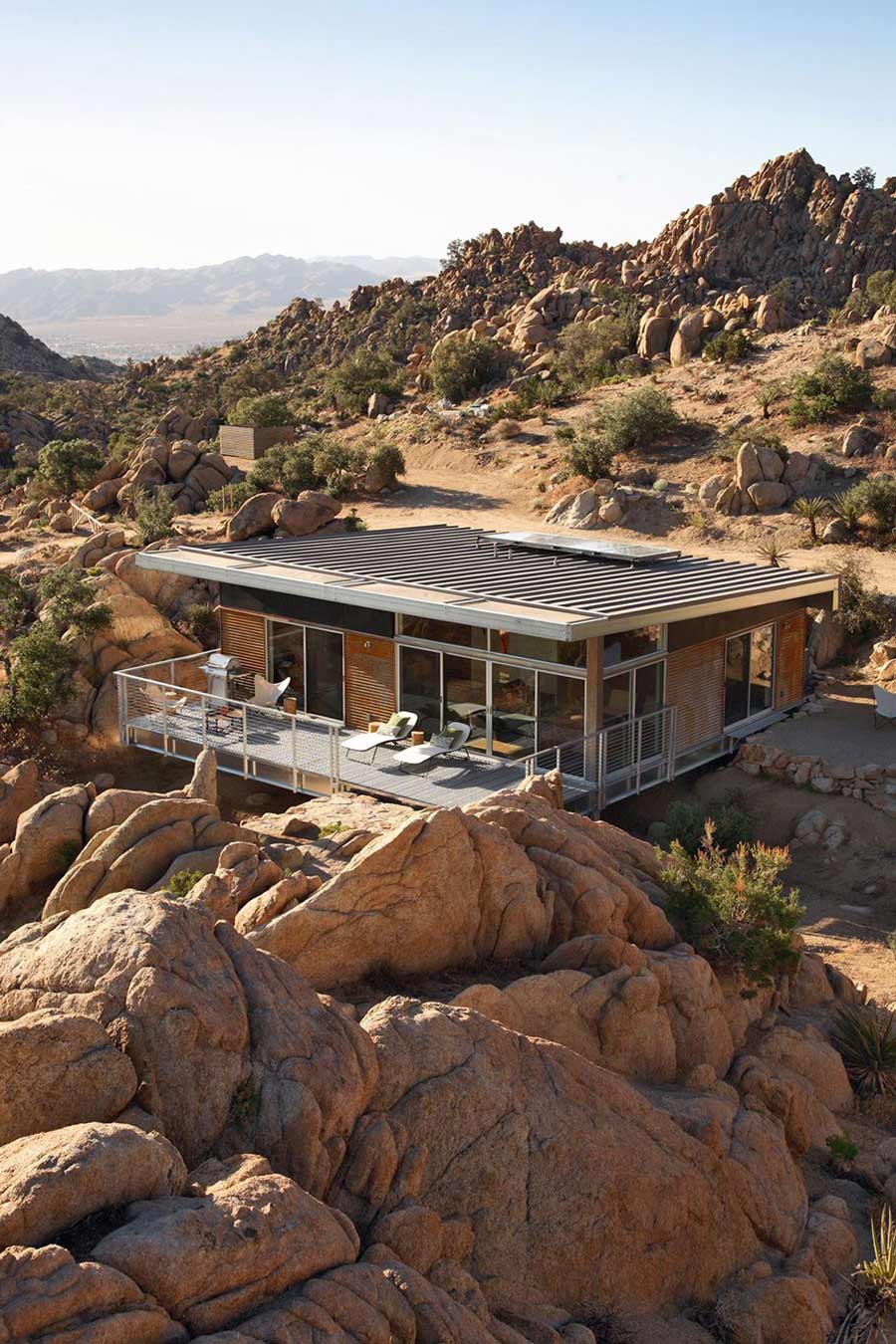

“This prefabricated home is located in an arid desert region north of Palm Spring, California. The homeowner asked for a modest size, open and adaptable floor plan that was sustainably conceived with durable materials. What’s more, the design was to utilize efficiencies of factory fabrication to achieve economical sales price. The design would serve as a prototype for a future line of prefabricated “system-built” homes. Emphasis was given to flexible site placement; and ensuring minimal environmental impact while maximizing view potential and required privacy.

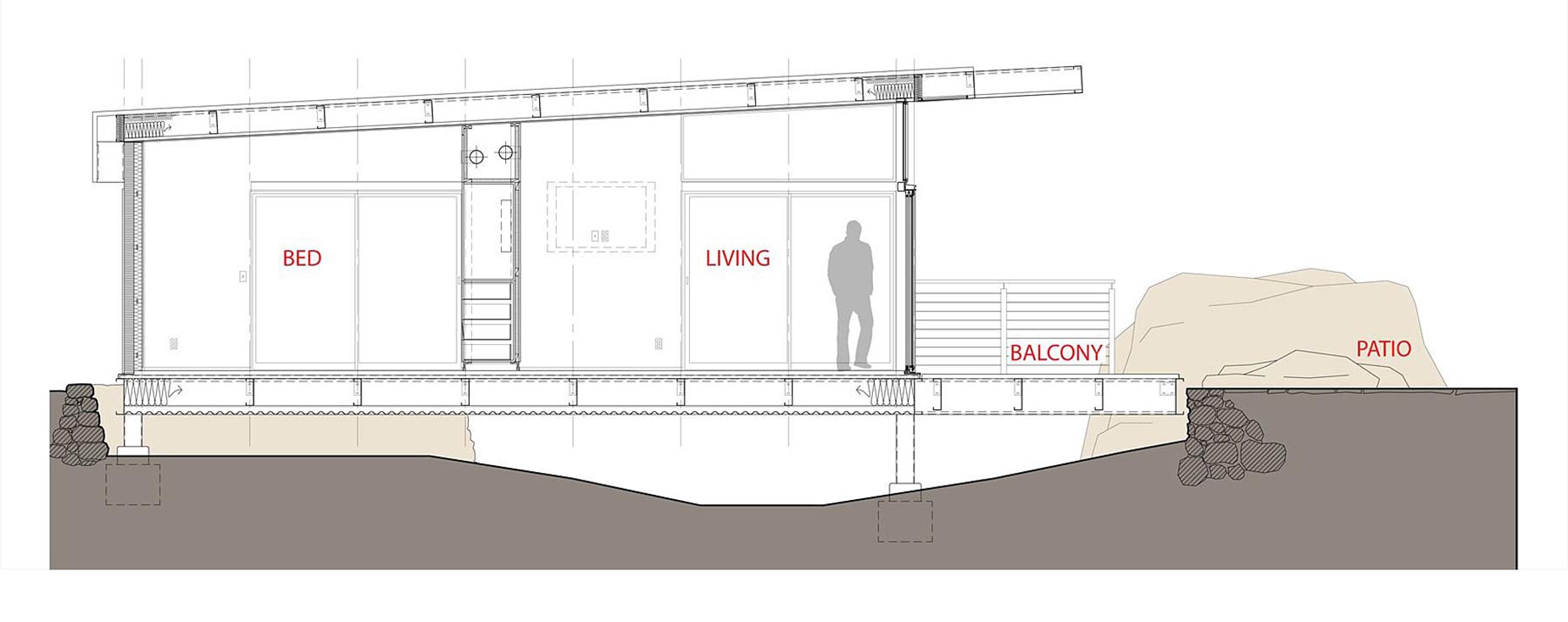

The modest 90 square meter, 2-Bedroom, 1-Bath house with seamless 30 square meter outdoor deck floats above the site on structurally efficient columns and beams of light gauge steel. Due to the homes location less than 25 kilometres from California’s infamous San Andres Earthquake Fault the design exceeds stringent seismic requirements. The building envelope is composed of modular Steel Thermal Efficient Panels, “STEP’s,” and standardized building components. The bathroom module, containing all home mechanical, plumbing, and electrical services, is built off-site and delivered finished with the flat packed “system-of-components”. Interiors are defined by the placement of storage cabinetry, eliminating interior framed walls. Solar technologies provide electricity, hot water and space heating.

The flat-packed building components minimize transportation volume and construction time (6-weeks start to finish). What’s more, the building system promotes sustainability through material and structural efficiency. The inherent nature of prefabricated design ensures low embodied energy and minimizes site waste. Low- & Non-V.O.C. products were used in all cabinetry and paint applications. The prototype was completed in May 2009, with an 8 week construction schedule at $270/SF.”

Comments